Wireless Crane Control: Innovation in Industrial Operations

From assembly to towing, your industry relies on cranes for your industrial process. Their many uses allow them to offer mechanical advantage across industries.

It is common for an operator to sit in the crane’s cab and maneuver the machine from within. They rely another person for guidance. This guidance can be communicated with hand signals.

Alternatively, in place of an operator that controls the crane from within the cab, an operator may use a hoist pendant push button station that is suspended on the outside of the unit. This method tends to be a wasteful use of a workforce.

Wireless remote control technology was introduced in the 1960s. Technology’s Innovative advancements continue to improve features. This contributes to easier integration for commercial applications.

How Do Radio Remote Control Crane Systems Work?

A remote control system consists of two mutually dependent parts:

1)A portable radio controller that transmits a control signal

2) A receiving device that is installed on the crane that is connected to all of the crane’s motor functions.

The controller emits a unique sequence of radio waves that correspond to the coded command for the button you’ve pushed. The receiving device then decodes the command which allows the crane to perform the intended function.

One of the greatest advantages of radio control systems is their range. Radio frequencies in control systems can be transmitted up to 100 feet and through physical barriers, like walls.

Advantages of Radio Remote Control Systems for Cranes

Safety

Regulatory bodies that set industry guidelines and standards for safety are continuously adopting more and more measures that put the health and well-being of employees at the forefront of all operational procedures. With that in mind, integrating wireless remote control systems for cranes is a proactive step that a business can take towards a more safe operation.

Wireless remote controls, unlike pendant push button controls, allow cranes to be operated independently, at a distance from the machine. Which permits the operator’s separation from potential dangers or hazardous work zones.

This also gives the operator the ability to simultaneously monitor data feedback such as the crane’s critical operating parameters that would give early detection of any operational dangers.

Efficiency

Wireless crane control systems improve productivity, precision, accuracy and speed of movement which has an enormous impact on the project forecasting, workflow and profitability of your operation.

In the case of traditional crane operation practices, the addition of a wireless remote control helps you to maximize your workforce productivity by allowing one of individuals who would be needed to perform as either a floor walker or a cab-mounter operator to be used elsewhere.

This would, in some cases, also remove the need for a walking aisle. The reduction of manpower and space needs creates conditions for an optimized workflow and quicker project completion rates.

Reliability

The reliability of a

radio control system lies in its programmed encode-decode sequence. You’ll need an experienced programmer to ensure that the radio frequency that your circuit uses is protected against accidental transmissions and interference. This way, only the transmission codes that use the programmed binary sequence for your crane will be recognized and decoded.

In respect to the longevity of a radio remote control system, modern technologies now allow systems to fulfill a lifespan between 10-20 years due to the ability of components to be replaced independently rather than the whole system which also means less downtime in cases of equipment failure.

Are Radio Remote Controls Right For Your Crane?

Cranes that will serve to benefit the most improvement with a radio control system are those who are used 20-80% of the time. These cranes typically have assigned cab operators who may be sitting idle most of their shift until the crane is needed. A radio control system would allow the operator to quickly switch between crane operation and any other tasks they are assigned to without having to constantly mount and unmount the equipment.

While you may purchase cranes that are built with radio communication capabilities, retrofitting your preexisting cranes is often a more practical and inexpensive alternative for many business owners.

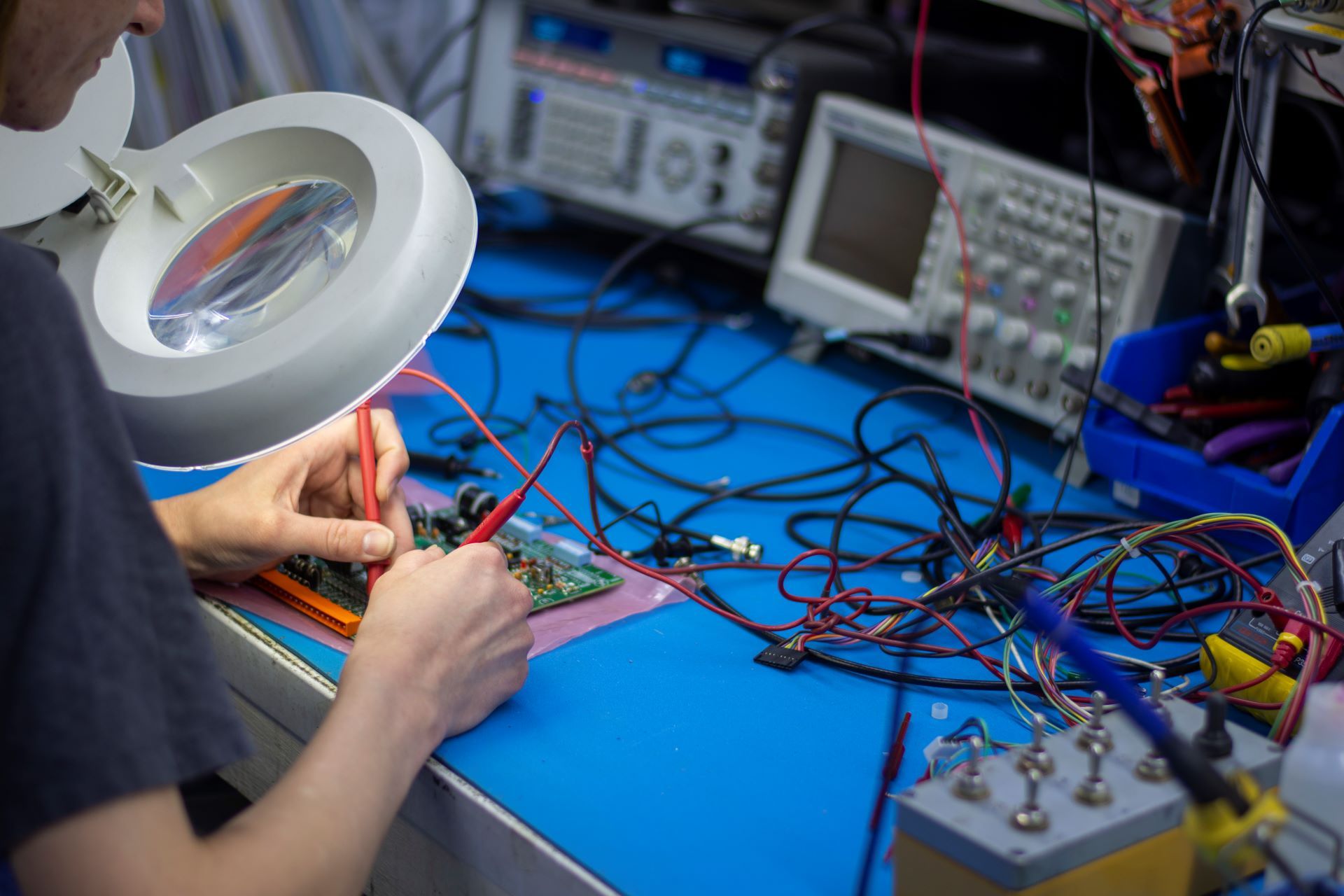

Retrofitting or

converting cranes to radio control systems should be done by an experienced engineer. A professional contractor can convert the current operational system to a radio circuit that can perform with operational flexibility so the previous cab or pedant control does not interfere with the radio control.

Microtronics has 30 years of experience in engineering and

manufacturing wireless remote controls for industrial manufacturers who build parts and equipment for industries such as agriculture, mining and aggregate, towing and military and law enforcement.

We pride ourselves on providing expert service to companies who are ready to streamline their operations with the help of wireless remote control products.

Call us today at to learn more about how we can help you upgrade your machine workforce and maximize your company’s potential.

Contact Us

Recent Microtronics Blog Posts

PROUDLY MADE IN U.S.A.

Microtronics, LLC. is a manufacturing company located in Iola, Kansas that

specializes in producing wireless devices to control virtually anything electrical or

hydraulically operated. We have been an industry leader since 1991.

MICROTRONICS, LLC

2270 US HIGHWAY 54

IOLA, KS 66749

PHONE: (620) 299-2903

© Copyright 2024 Microtronics, LLC. All Rights Reserved | Web design by Tekkii