Remote Control Technology In Mining Operations

Automation and Mining Industry Trends

Technology trends have been a huge growth factor in the

mining and excavation industry in the past decade. Automation tools and digital technologies meet the demands for enhanced operational performance and improved production volume. These advancements allow for production to continue through events that would usually cause lengthy downtimes. They also provide a means for operation in environments that are unsuitable or hazardous for human equipment operators.

How Remote Control Technologies Improve Mining Performance

High performing radio remote control tools have the ability to fine-tune all mining and excavation operations to include improvements in network connectivity, operational flexibility and location- independent operations, and decreased labor costs. This greatly increases safety conditions and saves in labor costs. Refinements in these areas give mining operations the conditions that promote expansion and keep up with modern industry demands.

Adaptable Equipment Operation

Without the need for mining equipment to be controlled from within the cab, projects require less operators to complete complex tasks remotely. Remote controls give an operator functionality of one or more machines from distances up to 1,250 miles away from the excavation site. Heavy mining equipment such as drills, shovels and haulers can be controlled by one operator from a singular location. This form of operation offers the advantage of a beneficial vantage point and saves in time and costs of manpower.

Built for Mine Expansion

Automation positions your mining operation for undertaking operational transitions. Radio remote controls not only enhance performance of mining equipment, but also offer highly repeatable results. This allows operation managers to be able to measure and track project fulfillment on a continuous cycle and make necessary adjustments to fit small or large-scale projects. These adjustments and predictions are easily utilized for the purposes of budgeting and planning.

Improved Network Connectivity

The success of a mining and excavation operation is fully dependent on its network connectivity. Automation makes it possible for a network of dispatchers and operators to share information and deploy production fleets in real time using remote control systems.

Remote Controls Enhance Operations

To build a mining ecosystem that performs efficiently and with cutting edge innovations, it’s necessary to incorporate radio remote control systems into your operations. The benefits include:

- The improvement of safety conditions

- Lowered labor and operation costs

- Mining performance that is adaptable for projects of all sizes.

- Improved mining network connectivity.

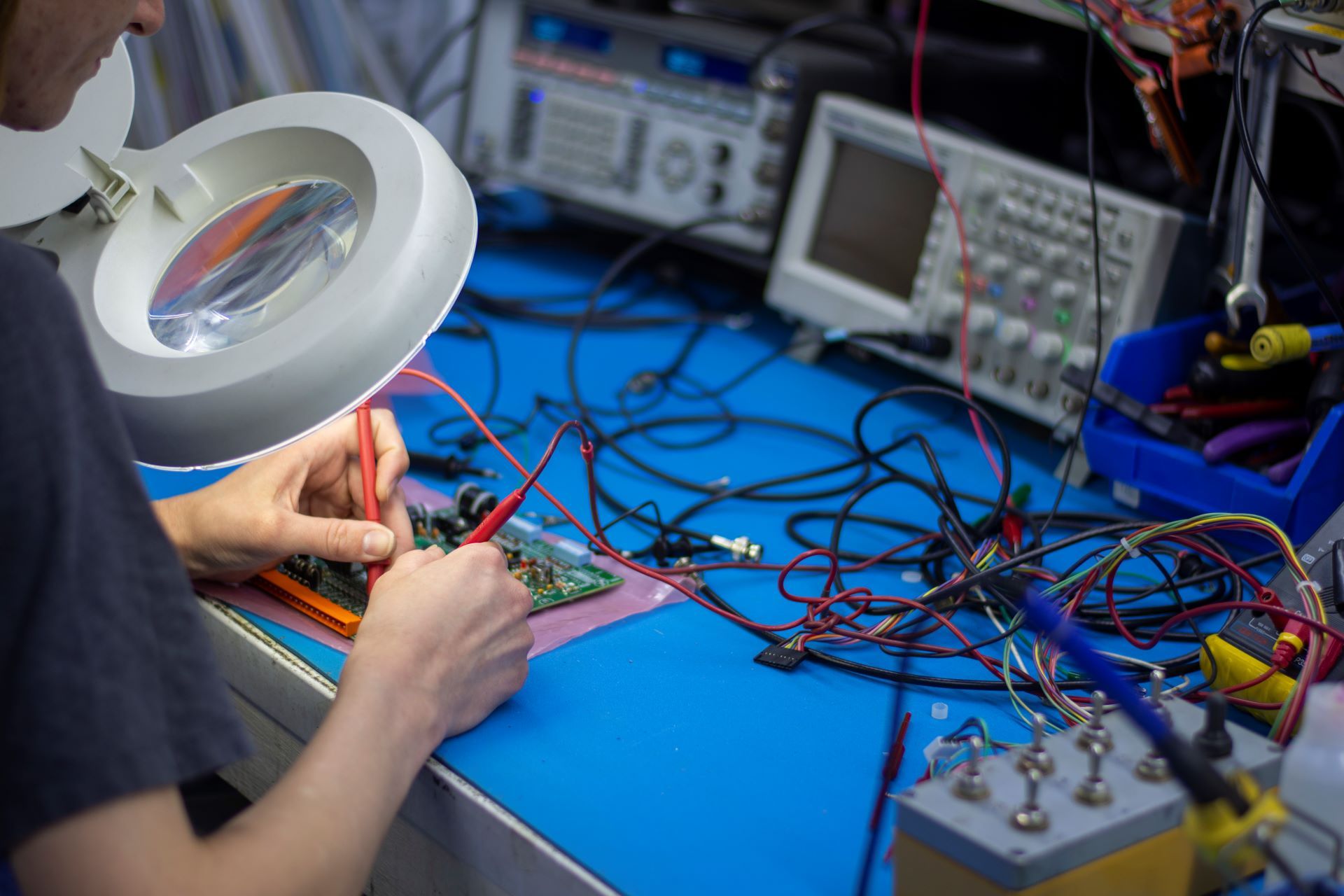

For 29 years, Microtronics, LLC. has been improving manufacturing industries through wireless control systems and electric engineering design. We can assist you in building a new fleet that includes a network of remote controlled equipment or retrofit pre-existing equipment with wireless control capabilities.

To learn more about how

Microtronics, LLC can integrate radio remote control systems into your mining operation,

fill out a contact form here.