What is an Industrial Control System?

Many different industries use Industrial Control Systems, so no matter what your area of expertise is, you’re likely to encounter the term at some point. If you aren’t familiar with Industrial Control Systems (or ICS), though, it can be a confusing topic to research.

Helpful advice is hard to find if you don’t already have a basic knowledge of the hardware and software in an ICS. Articles online can range from a little confusing to incomprehensible. When you add in the different ways industries use ICSes, it’s a real mess to navigate.

As leaders in wireless control for over 25 years, we at Microtronics want to take the mystery out of ICSes for you.

What Is An ICS?

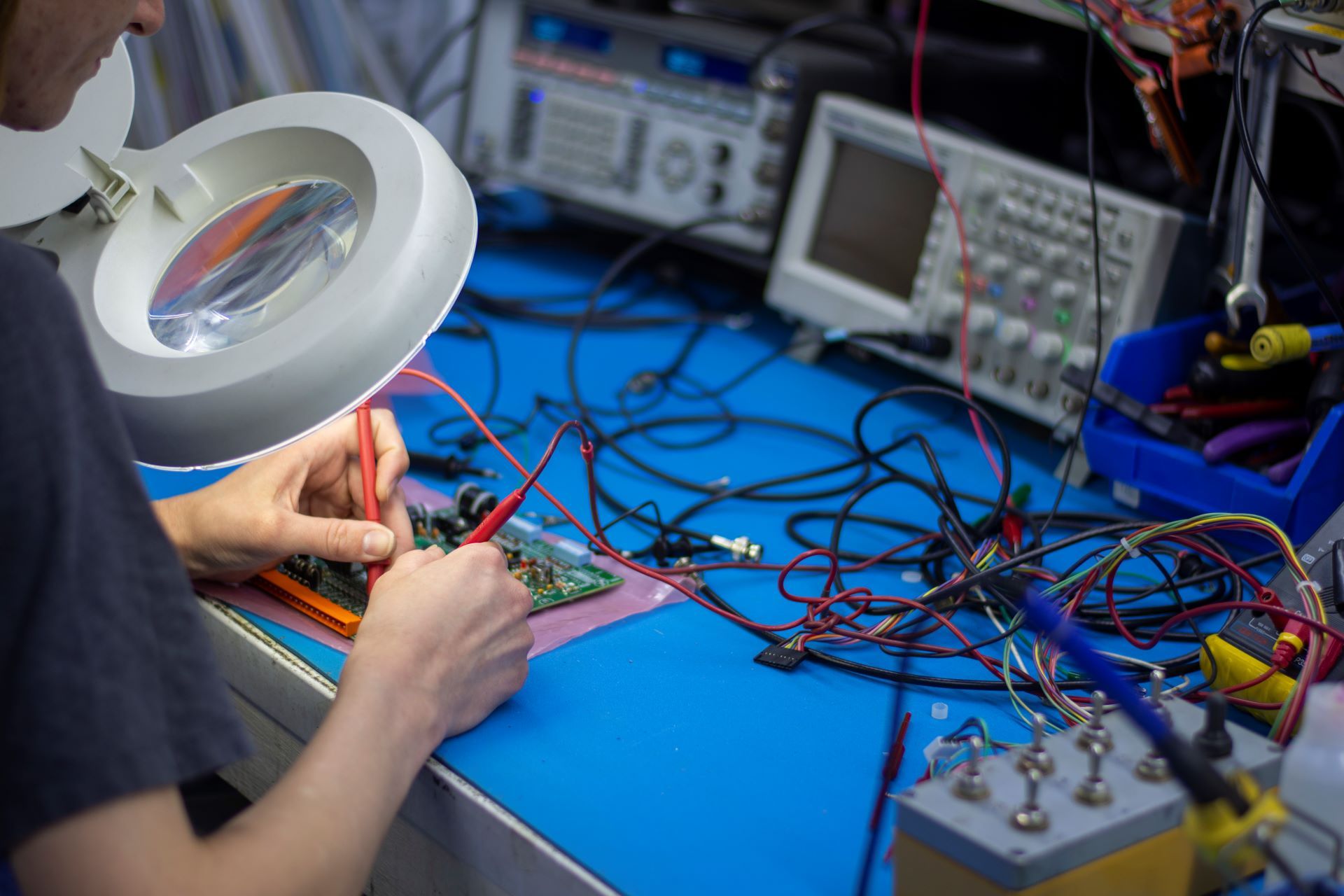

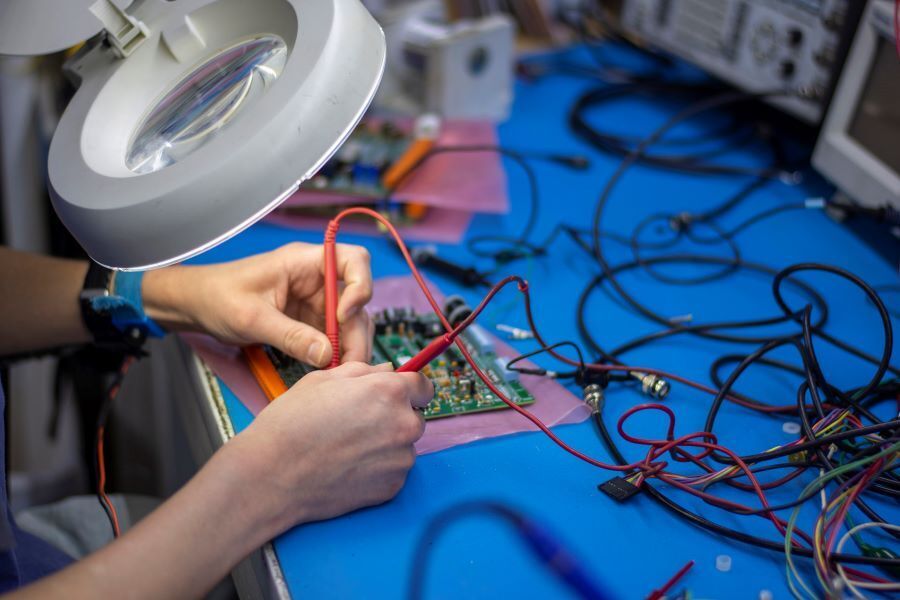

First, a basic definition. An ICS is a combination of hardware and software. It’s used to control different industrial processes efficiently and automatically.

Every ICS functions differently, depending on the unique needs of the production system using it. These three types of electrical control are the most common:

- Supervisory Control And Data Acquisition (SCADA) — A SCADA system helps monitor long-distance sites. Like the name says, this system operates in a supervisory role. Pipelines, water treatment systems, and electrical power transmissions all use SCADA as part of their ICS.

- Distributed Control Systems (DCS) — A DCS controls production in a single location. It can help mistakes in one area from impacting the whole system, and can be connected to a supervisory system like a SCADA for a larger network. Chemical plants, refineries, and paper mills all use DCSes.

- Programmable Logic Controllers (PLC) — PLCs can do a wide range of things. They can be modular or integrated with a whole system depending on the functions needed. PLCs are used by automobile industries, electric suppliers, and even the travel industry.

No one uses just one type of control. These are all part of the larger system. When they’re put together, they form your unique Industrial Control System.

How Can An ICS Help?

An ICS has a few main benefits. Let’s go over the ones that can help anyone, regardless of industry or operation size.

First, an ICS increases safety for yourself and your employees. With an ICS, it’s easier to shut things down when there are problems. You can stop machinery remotely before going in to solve the problem.

Secondly, an ICS increases reliability and consistency. Being a machine means that the ICS makes your production system more predictable. This carries all the way through the process to the final product.

Finally, an ICS is highly efficient. Automation means you waste less time and energy.

Doesn’t An ICS Have Drawbacks?

Of course. Like anything, ICS isn’t perfect. It still has its limitations, and it’s changing and being updated with new technology. The struggles you’ll have with ICS can be solved by having a good team to take care of the system for you.

It’s like your car. You have a go-to mechanic you trust with your car. When it needs regular maintenance or breaks down, you have someone to call. ICS is just the same. You’ll need to do regular preventative maintenance to get the best out of your system. Breakdowns will happen occasionally, but a good team will be there for you when it does.

Getting Started With An ICS

There are lots of moving parts to an ICS, literally and figuratively. The best way to get started with an ICS is by contacting a professional .

We can help you with determining what kind of ICS is right for you. Once you’ve made your decision, we can get it set up for you. Your business can be on track for a safer, more efficient work environment in no time.