Benefits of Utilizing Remote Controlled Heavy Machinery

Remote Controlled Heavy Machinery technology has become a new market segment for most major compact equipment manufacturers. The utilization of remote control usually eliminates the need for the operator to be in direct contact with the running machine. Essentially, this implies that the operator can position themselves in a safer place, farther away from the moving parts, harmful dust, noise, vibration, or any falling debris.

This allows greater ease of machine operation, less operator fatigue, and increased efficiency and productivity. Some of the industries that can benefit from the use of remote control include construction, mining, and agriculture, among others. Here are the benefits of utilizing remote-controlled heavy machinery.

1. Diverse Workforce

Remote control technology can appeal to a younger audience who are aware of the physical toll that comes with manual labor. Using remote control does not fatigue an operator's body in the same way that running manual heavy machinery does, operators are able to avoid injury and stay in the workforce for a longer period of time.

Reducing the physical requirements of brute strength also expands the labor pool available to contractors who are looking to find and retain skilled and experienced operators. This can potentially reduce downtime for operators and decrease the risk of injury on the job.

2. Remote Controlled Heavy Machinery Promote Health and Safety

There are many health and safety benefits associated with the use of remote controlled heavy machinery. Since the machines are operated at a distance, there is no need for the operator or laborers to physically be in contact with the machine when the work is taking place. Some structures may get unstable while deconstruction work is carried out and this can pose dangers for handheld machines.

Also, there is a risk of falling debris along with other potential safety and health threats. However, with the advent of remote-controlled machines, such safety and health risks are eliminated.

3. Latest Advancements

Every year, technology has a way of innovating and advancing faster than other segments of the industry. Remote-control technology is no exception. Instead of using a large remote control that straps over an operator's neck, some manufacturers have developed systems that provide a convenient, easily accessible, way to operate compact equipment using state-of-the-art remote control innovations.

The addition of remote-control technology could improve almost every aspect of your business – from your bottom line to the way you recruit and retain heavy machinery operators.

4. Non-Stop Productivity

For many decades, people have employed mechanization as a way of making strenuous tasks easier and more efficient. For instance, on a demolition site, where the use of handheld pneumatic breakers and other highly physical methods have been commonplace, employing a remote-controlled demolition machine can revolutionize productivity.

A remote-controlled machine can access some of the most restrictive job sites, such as those with dust, vibration, noise restrictions, as well as low floor loads. This allows contractors to greatly increase efficiency by employing heavy-hitting machines in applications previously limited to large crews with handheld equipment. Remote-controlled demolition machines with the right attachments can do the job of several common compact machines, including skid steers and mini excavators. This allows contractors to increase productivity without having to expand their fleet.

5. Better Return on Investment (ROI)

For many contractors, safety and efficiency are significant drivers for investing in machine control. Remote-controlled machinery touches many ROI opportunities; labor costs, machine costs, material costs, and faster job completion.

The machines enable operators to move materials faster and more accurately with fewer passes. Not only does the job get finished quickly, but fuel costs are minimized and the less experienced operators become more productive.

Why Choose Microtronics, LLC

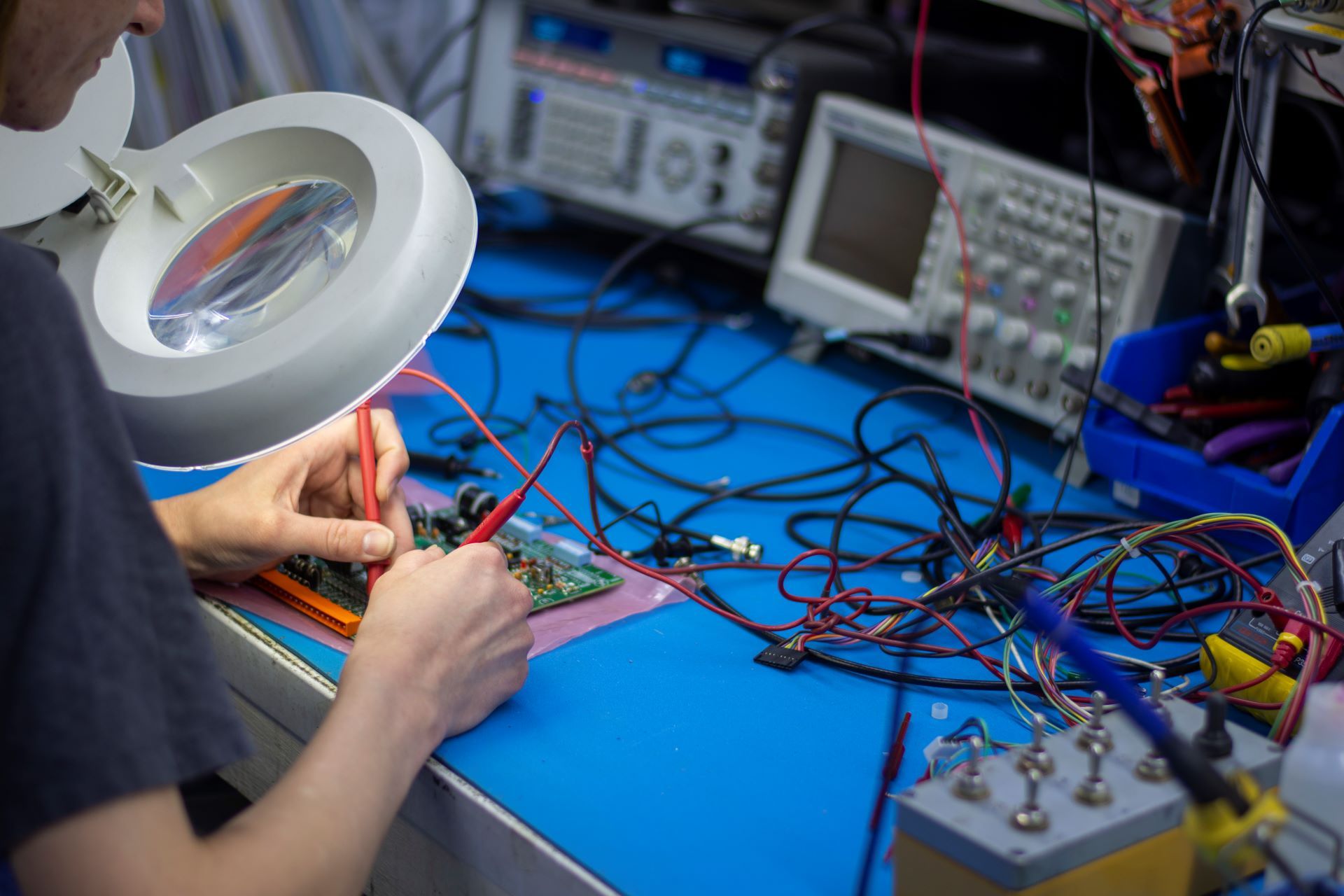

Microtronics is your number one source for Wireless Remote Control Products. From track vehicles to tub grinders, from bulk feeders to concrete pumps, material handling cranes, locomotives, and trucks. Microtronics is sure to have a product to fit your application.

Existing heavy machinery can be retrofitted with a wireless control system. So, even if you didn't purchase equipment with wireless capabilities, a radio control system can be added. If you have existing heavy machinery and are interested in adding an industrial wireless control solution, please contact Microtronics today! Or, if you manufacture heavy machinery, learn how adding remote controlled heavy machinery capabilities can increase demand for your equipment!

Contact Us

Recent Microtronics Blog Posts

PROUDLY MADE IN U.S.A.

Microtronics, LLC. is a manufacturing company located in Iola, Kansas that

specializes in producing wireless devices to control virtually anything electrical or

hydraulically operated. We have been an industry leader since 1991.

MICROTRONICS, LLC

2270 US HIGHWAY 54

IOLA, KS 66749

PHONE: (620) 299-2903

© Copyright 2024 Microtronics, LLC. All Rights Reserved | Web design by Tekkii